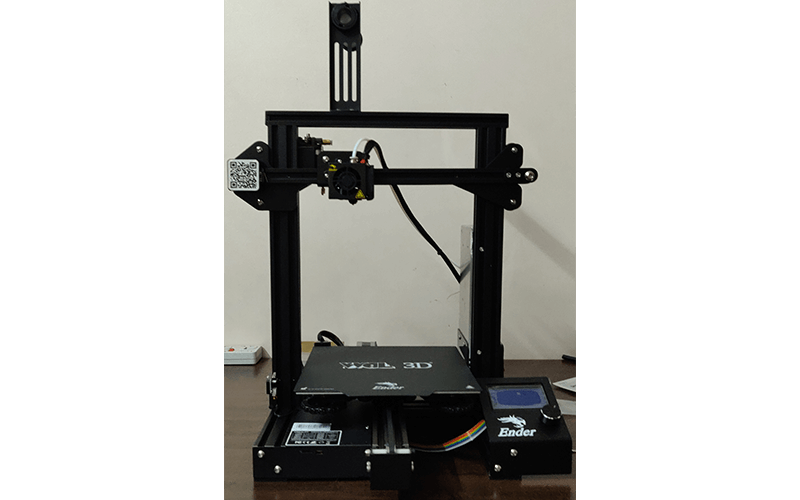

3D Printer FDM Creality Ender 3 Pro Review

I wanted an FDM 3D printer in my home lab for years or so, now I bought a 3D printer from creality Ender 3 Pro, which I feel is best in the market for beginners to enter 3D printing world. I feel for hobbyists who can make there own gears, servo motor holder, raspberry pi case, customized table top accessories, characters, home automation and RC drones and aircraft PCB holder etc.. Actually this makes your life easier to present you prototype to the world.

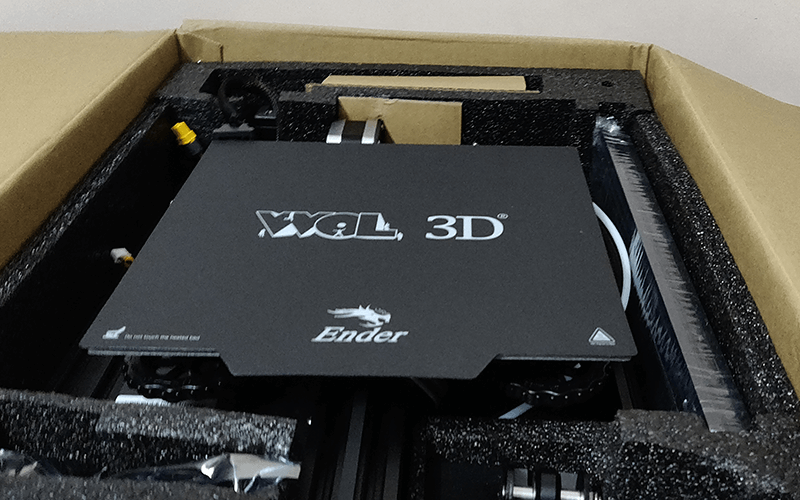

PRINTER PACKAGING

The 3D printer from Creality Ender 3 Pro came very well packed – you receive a semi assembled kit, which contains even he tools required to assemble. Please find the images of the packaging below.

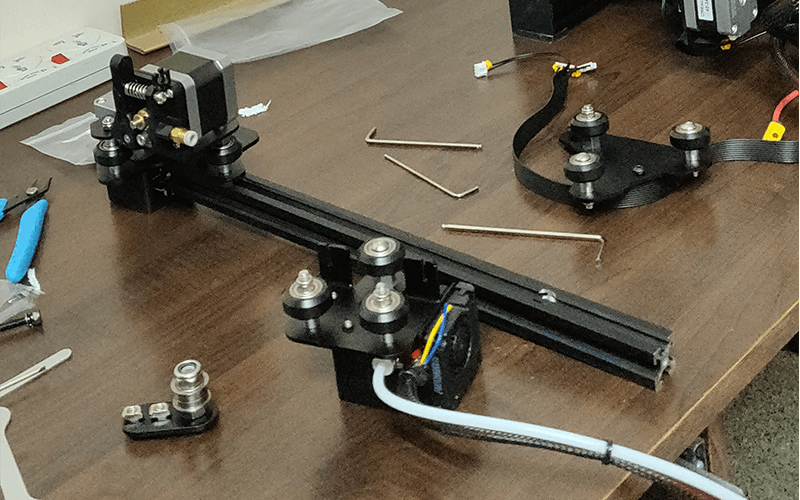

ASSEMBLY

It took me around an 2 hours to assemble it and power it up. All the assembly parts come with high precision and fits very well. All the different size bolts come in different packets with naming which makes it easier for anyone to assemble. There is a instruction manual to assemble which illustrates using the pictures which makes it smoother and also creality has a video for it online or you can just browse Instagram the SD which is provided in the kit, which has manuals, troubleshooting, assembly video, software and samples models are also included . There is lot of blogs and videos easily available on a quick google search( Please leave a comment or contact me from contact page if any issue or problem). A small sample filament is also included in the kit for your first few prints.

Tools included in the kit

- Pliers

- Wrench

- cable tie

- Blade

- Needle for nozzle cleaning

- Allen Key

- Screw driver

PROS AND CONS

PROS

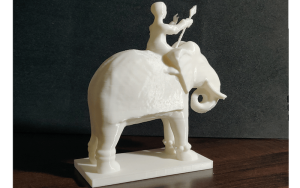

- Print quality is quite decent

- Good printing bed

- Magnetic print surface, easy for removal of print

- Large community size, any issue/problems can get solution online

- Affordable

- Power off – resume print recovery

CONS

- Manual bed leveling is required.

- Belt tightening maintenance is required frequently

- I have encountered the filament getting stuck to Z axis rod, hence require filament guide.

- Nozzle clogging

SOFTWARE USAGE FOR PRINTING

The software for creating the sliced model is also included in the kit. It’s called CREALITY SLICER, it’s very easy to install. Software support quite a large range of file extension like Stl, obj, dae, amf etc.

Generalized steps for 3D printing,

- Import the the model into the CREALITY SLICER with any extension mentioned above.

- Arrange the model on the heat bed with optimized usage of material and space

- Select the profile and material type on the left column options.

- See if it requires support structures, you can check the on the top left corner from a camera icon –> select over hang option, you will be able to see the overhangs in red color. If support required, then check the option on the left column.

- Save the Gcode file in the SD card.

- Insert and start printing.

SPECIFICATIONS

Modeling Technology: FDM (Fused Deposition Modeling)

Power Supply: Mean Well UL certified power supply

Printing Size: 220*220*250mm / 8.6×8.6×9.8 inches

Machine Size: 440*410*465mm / 17.3×16.1×18.3 inches

Package weight: 8.6kg / 19 lbs

Max Traveling Speed: 180mm/s

Filament: 1.75mm ABS/PLA,WOOD,FLEXIBLE,Carbon firber,PA….

Input: AC 100-265V 50-60Hz

Output: DC 24V 15A 360W

Layer Thickness: 0.1-0.4mm

Nozzle diameter: 0.4mm

Precision: ±0.1mm

File Format: OBJ, G-Code, STL(in CURA converted to G-Code)

Working Mode: USB cable (not included) online compatible or micro-SD (offline)

Max Nozzle Temperature: 255℃

Max Hotbed Temperature: 110℃

FOR WHOM IS THIS PRINTER RECOMMENDED AND IS IT WORTH TO BUY IT?

It’s a budgeted 3d printer for beginner who want to build models for there projects in-house. You get this printer for just in approx. 20000/- INR in which you a huge satisfaction of print quality. However, there is a saying that all the things you get is what you pay for apply’s here as well. There are some normal issues every FDM printer has, which hold s for this printer as well.